Ngokuthuthuka kobuchwepheshe bokugcina, izindawo zokugcina izimpahla ezinendlela emine ziye zashintsha kancane kancane izixazululo zesitoreji esivamile, futhi zaba ukukhetha kokuqala kwamakhasimende ngenxa yezindleko eziphansi, umthamo omkhulu wokugcina, kanye nokuguquguquka. Njengomthwali obalulekile wezimpahla, ama-pallets adlala indima ebalulekile ekugcinweni kwempahla. Ngakho yiziphi izidingouhlelo lokugcina lwezindlela ezinengamaphalethi?

1.Pallet Material

Amaphalethi angahlukaniswa cishe abe ngamaphalethi ensimbi, amapulangwe okhuni namapulangwe epulasitiki ngokuya ngezinto ezahlukahlukene.

Imvamisa, amaphalethi enziwe ngokhuni namaphalethi epulasitiki ngokuvamile asetshenziselwa ukuthwala izimpahla ze-1T noma ngaphansi, ngoba amandla azo okuthwala umthwalo anomkhawulo, futhi izindawo zokugcina izimpahla eziminyene zinezidingo eziqinile ekuphambukeni kwamaphalethi (≤20mm). Yebo, kukhona namaphalethi enziwe ngokhuni asezingeni eliphezulu noma amaphalethi epulasitiki anamashubhu amaningi anomthamo wokuthwala umthwalo omkhulu kuno-1T, kodwa masingakhulumi ngalokhu okwamanje. Ngemithwalo engaphezu kwe-1T, sivame ukuncoma amakhasimende ukuthi anikeze okuncamelayo kumapulangwe ensimbi. Uma kuyindawo yokugcina ebandayo, sincoma amakhasimende ukuthi akhethe ama-pallets epulasitiki, futhi kungcono kakhulu ukumelana namazinga okushisa aphansi njengoba ama-pallets ensimbi ejwayele ukugqwala endaweni yokugcina ebandayo futhi ama-pallets okhuni ajwayele umswakama, okwenza ukugcinwa kamuva kube nzima kakhulu futhi kubiza kakhulu. Uma ikhasimende lidinga inani eliphansi, sivame ukuncoma ama-pallets okhuni.

Ngaphezu kwalokho, ama-pallets ensimbi ngokuvamile ane-deformation ethile phakathi nenqubo yokukhiqiza, okwenza kube nzima ukufeza ukuvumelana; ama-pallets epulasitiki abunjiwe futhi abe nokuvumelana okungcono; ama-pallets okhuni awonakaliswa kalula ngesikhathi sokusetshenziswa futhi awavamile ekukhiqizeni. Ngakho-ke, lapho bobathathu behlangabezana nezidingo, sincoma ukusebenzisa ama-pallets epulasitiki.

I-Pallet yensimbi

Iphalethi Yokhuni

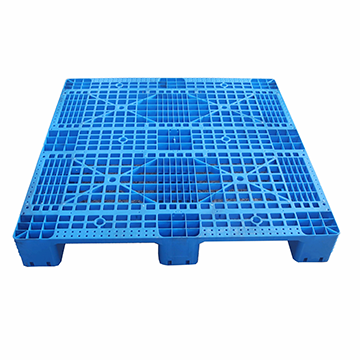

Iphalethi yePlastiki

2.Isitayela sePallet

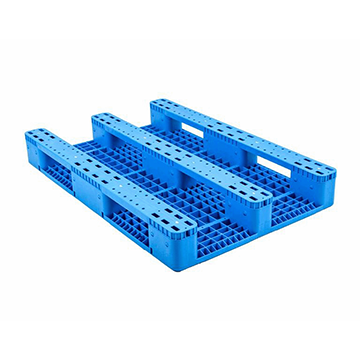

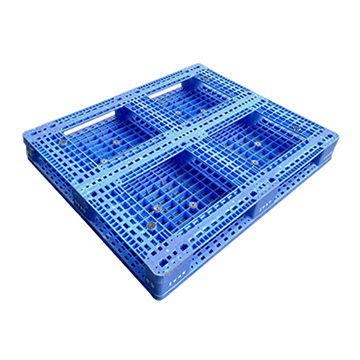

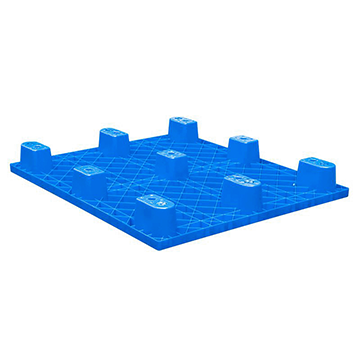

Amaphalethi angahlukaniswa cishe abe yizinhlobo ezilandelayo ngokuya ngezitayela zawo:

Imilenze emithathu ehambisanayo

Imilenze Yesiphambano

Izinhlangothi ezimbili

Izinyawo eziyisishiyagalolunye

ukungena kwezindlela ezimbili

ukungena ngezindlela ezine

Ngokuvamile asincomi ukusetshenziswa kwe-pallet enezinyawo eziyisishiyagalolunye kanye ne-pallet yokungena yezindlela ezimbili ekhonjiswe emfanekisweni osendaweni yokugcina impahla enezinhlangothi ezine. Lokhu kuhlobene nendlela yokugcina i-rack. I-pallet ifakwe kumathrekhi amabili ahambisanayo futhi i-shuttle yezindlela ezine isebenza ngaphansi kwayo. Ezinye izinhlobo zingasetshenziswa ngokujwayelekile.

3.Usayizi wephalethi

Usayizi we-pallet uhlukaniswe ububanzi nokujula, futhi ngeke sikunake ukuphakama okwamanje. Ngokuvamile, izindawo zokugcina izimpahla eziminyene zizoba nemikhawulo ethile ngosayizi we-pallet, njengokuthi: isiqondiso sobubanzi akufanele sidlule i-1600 (mm), isiqondiso sokujula akufanele sidlule i-1500, futhi i-pallet enkulu, kuba nzima nakakhulu ukwenzai-shuttle yezindlela ezine. Nokho, le mfuneko ayiphelele. Uma sihlangabezana ne-pallet enobubanzi obungaphezu kuka-1600, singakwazi futhi ukuklama usayizi we-shuttle ofanele wezindlela ezine ngokulungisa isakhiwo se-rack rack. Kunzima uma kuqhathaniswa ukunwebeka endaweni ejulile. Uma kuyi-pallet enezinhlangothi ezimbili, kungase kube nohlelo lokuklama oluguquguqukayo.

Ngaphezu kwalokho, kuphrojekthi efanayo, sivame ukutusa ukusebenzisa usayizi owodwa we-pallet, okuyinto engcono kakhulu yokuthola imishini. Uma izinhlobo ezimbili kufanele zihambisane, siphinde sibe nemiklamo yezixazululo eguquguqukayo. Kuma-aisles we-inventory, sivame ukuncoma ukuthi ugcine kuphela amaphalethi anencazelo efanayo, futhi ugcine amaphalethi anezincazelo ezihlukile kuma-aisles ahlukene.

4.Umbala Wephalethi

Sivame ukuhlukanisa phakathi kwemibala emnyama, eluhlaza okwesibhakabhaka neminye embala we-pallets. Kumaphalethi amnyama, sidinga ukusebenzisa izinzwa ezinocindezelo lwangemuva ukuze zithole; kuma-pallets aluhlaza okwesibhakabhaka okumnyama, lokhu kutholwa kunzima kakhulu, ngakho-ke sivame ukusebenzisa izinzwa zokukhanya okuluhlaza okwesibhakabhaka; eminye imibala ayinazo izidingo eziphezulu, umbala ogqamile, umphumela wokuthola ungcono, umhlophe ungcono kakhulu, nemibala emnyama iba mibi kakhulu. Ngaphezu kwalokho, uma kuyi-pallet yensimbi, kunconywa ukuthi ungafafazi upende ocwebezelayo ebusweni be-pallet, kodwa ubuchwepheshe bepende ye-matte, obungcono ekutholweni kwe-photoelectric.

Ithreyi elimnyama

Ithreyi eluhlaza okwesibhakabhaka emnyama

Ithreyi ecwebezelayo ephezulu

5.Ezinye izidingo

Igebe elingaphezulu kwephalethi linezidingo ezithile zokutholwa kwe-photoelectric yemishini. Sincoma ukuthi igebe elingaphezulu kwephalethi akufanele libe likhulu kuno-5CM. Kungakhathaliseki ukuthi i-pallet yensimbi, i-pallet yepulasitiki noma i-pallet yokhuni, yegebe likhulu kakhulu, ayihambisani nokutholwa kukagesi wesithombe. Ngaphezu kwalokho, uhlangothi oluncane lwe-pallet aluhambisani nokutholwa, kuyilapho uhlangothi olubanzi lulula ukulubona; imilenze ebanzi ezinhlangothini zombili ze-pallet, ivumela kakhulu ukubonwa, futhi imilenze ibe mincane, iba yingozi kakhulu.

Ngokombono, sincoma ukuthi ukuphakama kwe-pallet nezimpahla akufanele kube ngaphansi kwe-1m. Uma ukuphakama kwesitezi kuklanyelwe ukuba kube phansi kakhulu, ngeke kube nzima ukuthi izisebenzi zingene endaweni yokugcina impahla ukuze zilungiswe. Uma kunezimo ezikhethekile, singakwazi futhi ukwenza imiklamo eguquguqukayo.

Uma izimpahla zidlula i-pallet, kunconywa ukuthi zingadluli ku-10CM ngaphambili nangemuva. Zama ukulawula ibanga eleqile, elincane kuba ngcono.

Ngamafuphi, lapho ukhetha indawo yokugcina impahla enendlela emine, amabhizinisi kufanele axhumane nomklami futhi abhekisele emibonweni yomklami ukuze azuze imiphumela eyanelisa kakhulu. I-Nanjing 4D Intelligent Storage Equipment Co., Ltd. igxile esitolo esinezindlela ezine eziminyene futhi inokuhlangenwe nakho okucebile kokuklama. Samukela abangani abavela ekhaya naphesheya ukuzoxoxisana!

Isikhathi sokuthumela: Nov-25-2024