-

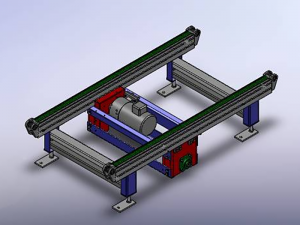

Isistimu yokuphakamisa isivinini esiphezulu

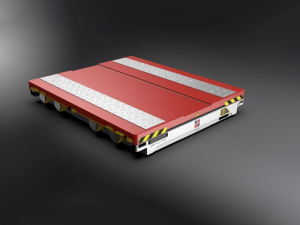

Ikheshi lephalethi elibuyiselanayo lakhiwe ikakhulukazi izingxenye eziyinhloko ezifana nedivayisi yokushayela, iplathifomu yokuphakamisa, ibhalansi ye-counterweight block, ifreyimu yangaphandle, kanye ne-mesh yangaphandle.

-

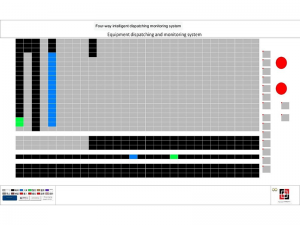

Ulwazi lwesistimu ye-shuttle yokuthutha ye-4D

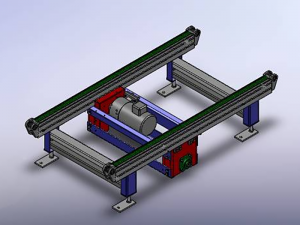

I-motor ishayela i-drive shaft eqenjini lokudlulisa, futhi i-drive shaft ishayela iketango lokudlulisa ukuze ibone umsebenzi wokudlulisa we-pallet.

-

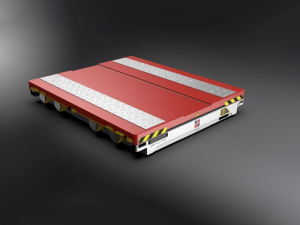

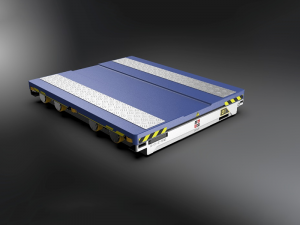

Uhlobo olujwayelekile lwesistimu ye-shuttle ye-4D

Njengemishini eyinhloko yendawo yokugcina impahla ehlakaniphile yezimoto ezinendlela emine, imoto eqondile nevundlile ikakhulukazi iqukethe ukuhlanganiswa kwama-rack, uhlelo lukagesi, uhlelo lokuphakelwa kwamandla, uhlelo lokushayela, uhlelo lwe-jacking, uhlelo lwezinzwa, njll.

-

4D Pallet Shuttle racking systems

Ishalofu leshelufu elinezinhlangothi ezine eliqinile lakhiwe ikakhulukazi izingcezu zama-rack, i-Sub-channel crossbeams, amathrekhi esiteshi esingaphansi, amadivayisi wenduku kathayi ovundlile, ama-cross beam amashaneli, Amathrekhi esiteshi esikhulu, Ukuxhunywa kwama-rack nomhlaba, izinyawo ezilungisekayo, ukudonsa emuva, ukuvikela. amanethi, izitebhisi zokulungisa, Impahla eyinhloko yeshalofu i-Q235/Q355, kanye nezinto zokusetshenziswa ze-Baosteel ne-Wuhan Iron and Steel zikhethwa futhi zakhiwe ngokugoqeka okubandayo.

-

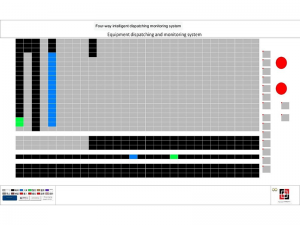

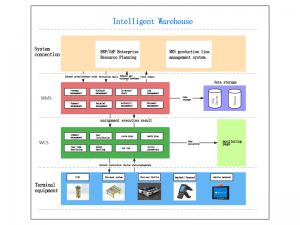

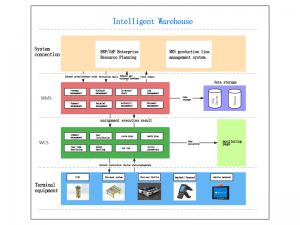

I-WCS-Warehouse Control System

Uhlelo lwe-WCS lubhekele ukuhlela phakathi kwesistimu nezinto zokusebenza, futhi luthumela imiyalo ekhishwa uhlelo lwe-WMS kumshini ngamunye ukuze kusebenze ngokuhlelekile.Kukhona ukuxhumana okuqhubekayo phakathi kwemishini nohlelo lwe-WCS.Lapho okokusebenza kuqeda umsebenzi, isistimu ye-WCS yenza ngokuzenzakalelayo ukuthumela idatha ngohlelo lwe-WMS.

-

Amasistimu we-shuttle we-4D wohlelo lokusebenza lomthwalo osindayo

Indlela ye-crossbar esindayo ngokuyisisekelo iyafana naleyo yenguqulo evamile, umehluko omkhulu ukuthi umthamo wayo wokulayisha uthuthukiswa kakhulu.Umthamo wayo wokuthwala uzofinyelela cishe ngokuphindwe kabili kunenguqulo evamile, futhi ngokuhambisanayo, isivinini sayo sokugijima esihambisanayo naso sizokwehla.Kokubili isivinini sokuhamba nokugijima sizokwehla.

-

Amasistimu we-shuttle we-4D wezinga lokushisa eliphansi

Isakhiwo senguqulo yezinga lokushisa eliphansi le-crossbar ngokuyisisekelo iyafana naleso senguqulo evamile.Umehluko omkhulu usezindaweni ezihlukene zokusebenza.Inguqulo yezinga lokushisa eliphansi le-crossbar isetshenziswa kakhulu endaweni engu-30 ℃, ngakho ukukhetha kwayo kwangaphakathi kwempahla kuhluke kakhulu.Zonke izingxenye zangaphakathi zinokumelana nezinga lokushisa eliphansi , ibhethri liphinde libe yibhethri elisezingeni eliphansi elisebenza kahle kakhulu, elingasekela ukushaja endaweni engu -30 °C.Ukwengeza, uhlelo lokulawula lwangaphakathi luphinde lwavalwa ukuze kuvinjwe amanzi okujiya lapho ukunakekelwa kuphumile endaweni yokugcina izinto.

-

Amasistimu we-shuttle we-4D wohlelo lokusebenza lwejubane eliphezulu

Indlela yenguqulo yesivinini esikhulu yemoto eqondile nevundlile iyafana naleyo yemoto evamile eqondile nevundlile, umehluko omkhulu usekuthuthukisweni kwejubane lokuhamba.Uma kubhekwa izimpahla ze-pallet ezivamile nezizinzile, ukuze kuthuthukiswe ukusebenza kahle okuphelele kwephrojekthi futhi kuncishiswe inani lama-crossbar asetshenzisiwe, kuhlongozwa inguqulo enesivinini esiphezulu se-crossbar.Inkomba yejubane lokuhamba iphindwe kabili kunenguqulo evamile, futhi isivinini se-jacking asishintshile.Ukuze kuthuthukiswe ukuphepha, i-laser yokuphepha ifakwe emishinini yokuvikela ingozi ekusebenzeni ngesivinini esikhulu.

-

I-Dense Racking ye-shuttles ye-TDR

Amarakhi aminyene ayingxenye ebalulekile yesistimu yokuqopha isitoreji esijulile.Ngokuvamile kubhekiselwa ekusetshenzisweni kwendawo ethile yokugcina impahla kanye nempahla yokugcina impahla ukuze kuthuthukiswe ukutholakala kwendawo yokugcina impahla ngangokunokwenzeka esimweni sendawo efanayo yokugcina impahla, ukuze kugcinwe imithwalo eyengeziwe.

-

Uhlelo lokuphathwa kwempahla ye-WMS

Uhlelo lwe-WMS luyingxenye ebalulekile yokuphathwa kwempahla, futhi luyisikhungo esihlakaniphile sokulawula impahla yokuphatha impahla, isikhungo sokuthumela impahla, kanye nesikhungo sokuphatha imisebenzi.Abasebenzisi ikakhulukazi baphatha yonke inqolobane ohlelweni lwe-WMS, ikakhulukazi okuhlanganisa: ukuphathwa kolwazi lwempahla eyisisekelo, ukuphathwa kwendawo yokugcina impahla, ukuphathwa kolwazi lwezimpahla, ukungena nokuphuma kwempahla, imibiko yamalogi neminye imisebenzi.Ukusebenzisana nohlelo lwe-WCS kungaqedela ngempumelelo ukuhlanganiswa kwezinto, Okungenayo, okuphumayo, ukusungula kanye nokunye ukusebenza.Kuhlanganiswe nesistimu yokusabalalisa indlela ehlakaniphile, indawo yokugcina impahla ingasetshenziswa ngokuzinza nangempumelelo.Ngaphezu kwalokho, uhlelo lwe-WMS lungaqedela ukuxhumana okungenamthungo ne-ERP, SAP, MES nezinye izinhlelo ngokuvumelana nezidingo zesayithi, okusiza kakhulu ukusebenza komsebenzisi phakathi kwezinhlelo ezahlukene.