-

I-AMR

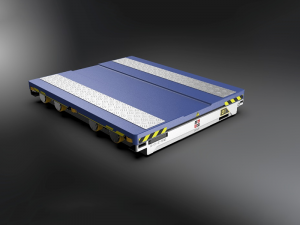

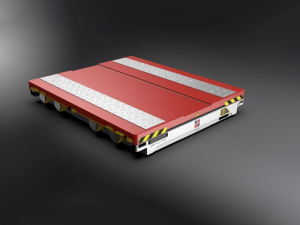

I-AMR trolley, iyimoto yokuthutha efakelwe izisetshenziswa zokuqondisa ezizenzakalelayo njenge-electromagnetic noma i-optical, engahamba ngendlela enqunyiwe, inokuvikela ukuphepha nemisebenzi ehlukahlukene yokudlulisa. Kuzicelo zezimboni, iyimoto yokuthutha engadingi umshayeli. Umthombo wayo wamandla ibhethri elishajekayo.

I-AMR ecwile emanzini: ngena ngaphansi kweloli lezinto ezibonakalayo, bese ugibela futhi uhlukanise ngokuzenzakalelayo ukuze ubone ukulethwa kwezinto kanye nemisebenzi yokugaya kabusha. Ngokusekelwe ekumisweni okuhlukahlukene nobuchwepheshe bokuzulazula, izimoto zokuthutha ezizenzakalelayo ezingadingi ukushayela umuntu sezizonke zibizwa ngokuthi yi-AMR.

-

I-Palletizer

I-palletizer ingumkhiqizo wenhlanganisela yezinto eziphilayo zemishini nezinhlelo zekhompyutha, Ithuthukisa ukusebenza kahle kokukhiqizwa kwesimanje. Imishini yokufaka i-palletizing isetshenziswa kabanzi embonini yokuhlanganisa. Amarobhothi ama-Palletizing angonga kakhulu izindleko zabasebenzi nendawo yaphansi.

Irobhothi le-palletizing liyavumelana nezimo, linembile, liyashesha, liyasebenza, lizinzile futhi liyasebenza.

Uhlelo lwamarobhothi ophahleni lusebenzisa idivayisi yerobhothi edidiyelwe, enezinzuzo zezinyathelo ezincane kanye nevolumu encane. Umqondo wokusungula umugqa wokuhlanganisa umshini webhulokhi osebenza kahle, osebenza kahle futhi owonga amandla ngokugcwele ungafezeka.

-

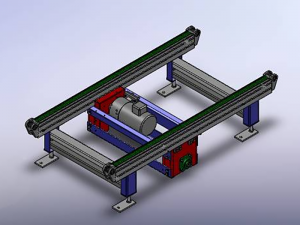

Umshini wokugoqa wethreyi

Umshini wokugoqa wethreyi umshini ozenzakalelayo, obuye ubizwe ngokuthi umshini wethreyi wekhodi, usetshenziswa ohlelweni lokudlulisa ithreyi, kuhlanganiswe nama-conveyor ahlukahlukene, ukusabalalisa amathreyi angenalutho kulayini wokudlulisa. Umshini wokugoqa wethreyi usetshenziselwa ukupakisha amaphalethi angawodwa ku-pallets stacking, okuhlanganisa: isakhiwo sokusekela ukupakisha kwe-pallet, itafula lokuphakamisa i-pallet, inzwa yomthwalo, ukutholwa kwesimo se-pallet, inzwa yerobhothi evulekile / evaliwe, i-lift, i-low, i-switch position central.

-

I-RGV

I-RGV imele i-Rail Guide Vehicle, ibizwa nangokuthi i-trolley. I-RGV isetshenziswa ezindlini zokugcina izimpahla ezinezindlela ezahlukahlukene zokugcina eziphakeme kakhulu, futhi ama-aisles angaklanywa ngokusho kwanoma yibuphi ubude ukuze kwandiswe amandla okugcina impahla yonke. Ngaphezu kwalokho, lapho usebenza, ungasebenzisa futhi iqiniso lokuthi i-forklift ayidingi ukungena endleleni, kuhlangene nokuhamba ngokushesha kwe-trolley endleleni, ingathuthukisa ngokuphumelelayo ukusebenza kahle kwendawo yokugcina impahla futhi yenze kube nokuphepha okwengeziwe.

-

Uhlobo olujwayelekile lwesistimu ye-shuttle ye-4D

Njengemishini eyinhloko yendawo yokugcina impahla ehlakaniphile yezimoto ezinendlela emine, imoto eqondile nevundlile ikakhulukazi iqukethe ukuhlanganiswa kwama-rack, uhlelo lukagesi, uhlelo lokuphakelwa kwamandla, uhlelo lokushayela, uhlelo lwe-jacking, uhlelo lwezinzwa, njll.

-

Amasistimu we-shuttle we-4D wezinga lokushisa eliphansi

Isakhiwo senguqulo yezinga lokushisa eliphansi le-crossbar ngokuyisisekelo iyafana naleso senguqulo evamile. Umehluko omkhulu usezindaweni ezihlukene zokusebenza. Inguqulo yezinga lokushisa eliphansi le-crossbar isetshenziswa kakhulu endaweni engu-30 ℃, ngakho ukukhetha kwayo kwangaphakathi kwempahla kuhluke kakhulu. Zonke izingxenye zangaphakathi zinokumelana nezinga lokushisa eliphansi , ibhethri liphinde libe yibhethri elisezingeni eliphansi elisebenza kahle kakhulu, elingasekela ukushaja endaweni engu -30 °C. Ukwengeza, uhlelo lokulawula lwangaphakathi luphinde lwavalwa ukuze kuvinjwe amanzi okujiya lapho ukunakekelwa kuphumile endaweni yokugcina izinto.

-

Amasistimu we-shuttle we-4D wohlelo lokusebenza lwejubane eliphezulu

Indlela yenguqulo yesivinini esikhulu yemoto eqondile nevundlile iyafana naleyo yemoto evamile eqondile nevundlile, umehluko omkhulu usekuthuthukisweni kwejubane lokuhamba. Uma kubhekwa izimpahla ze-pallet ezivamile nezizinzile, ukuze kuthuthukiswe ukusebenza kahle okuphelele kwephrojekthi futhi kuncishiswe inani lama-crossbar asetshenzisiwe, kuhlongozwa inguqulo enesivinini esiphezulu se-crossbar. Inkomba yejubane lokuhamba iphindwe kabili kunenguqulo evamile, futhi isivinini se-jacking asishintshile. Ukuze kuthuthukiswe ukuphepha, i-laser yokuphepha ifakwe emishinini yokuvikela ingozi ekusebenzeni ngesivinini esikhulu.

-

Amasistimu we-shuttle we-4D wohlelo lokusebenza lomthwalo osindayo

Indlela ye-crossbar esindayo ngokuyisisekelo iyafana naleyo yenguqulo evamile, umehluko omkhulu ukuthi umthamo wayo wokulayisha uthuthukiswa kakhulu. Umthamo wayo wokuthwala uzofinyelela cishe ngokuphindwe kabili kunenguqulo evamile, futhi ngokuhambisanayo, isivinini sayo sokugijima esihambisanayo naso sizokwehla. Kokubili isivinini sokuhamba nokugijima sizokwehla.

-

I-Dense Racking yama-shuttles we-4D

Ishalofu lendawo yokugcina impahla elinezinhlangothi ezine liqukethe ikakhulukazi izingcezu zama-rack, I-Sub-channel crossbeams, amathrekhi esiteshi esingaphansi, amadivaysi enduku kathayi avundlile, Imiphambano yesiteshi esikhulu, Amathrekhi esiteshi esikhulu, Ukuxhunywa kwama-rack nomhlabathi, izinyawo ezilungisekayo, ukudonsa emuva, amanetha okuvikela, izitebhisi zokunakekela, Impahla eyinhloko yeshalofu kanye ne-Q53 raw53 kanye ne-Q53. I-Wuhan Iron and Steel ikhethwa futhi yakhiwe ngokugoqa okubandayo.

-

Isistimu yokuphakamisa isivinini esiphezulu

Ikheshi lephalethi elibuyiselanayo lakhiwe ikakhulukazi izingxenye eziyinhloko ezifana nedivayisi yokushayela, iplathifomu yokuphakamisa, ibhalansi ye-counterweight block, ifreyimu yangaphandle, kanye ne-mesh yangaphandle.

-

Ulwazi lwesistimu ye-shuttle ye-4D yokuthutha

I-motor ishayela i-drive shaft eqenjini lokudlulisela, futhi i-drive shaft ishayela iketango lokudlulisa ukuze ibone umsebenzi wokudlulisa we-pallet.

-

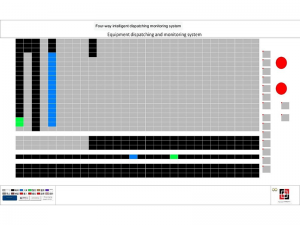

I-WCS-Warehouse Control System

Uhlelo lwe-WCS lubhekele ukuhlela phakathi kwesistimu nezinto zokusebenza, futhi luthumela imiyalo ekhishwe uhlelo lwe-WMS kumishini ngayinye ukuze isebenze ngokuhlelekile. Kukhona ukuxhumana okuqhubekayo phakathi kwemishini nohlelo lwe-WCS. Lapho okokusebenza kuqeda umsebenzi, isistimu ye-WCS yenza ngokuzenzakalelayo ukuthumela idatha ngohlelo lwe-WMS.